FMEA (Failure Mode and Effects Analysis) is an analytical methodology used to ensure that potential problems have been considered and addressed throughout the product and process development process.

A part of the evaluation and analysis is the risk assessment.

The key point is that a discussion is conducted regarding the design (product or process), the review of functions, and any change in application, and the potential failure risk that results from it.

AMDEC AIAG & VDA

Developed by an international team of experts, the new FMEA AIAG & VDA manual integrates the best practices of AIAG and VDA methodologies into a harmonized and structured approach.

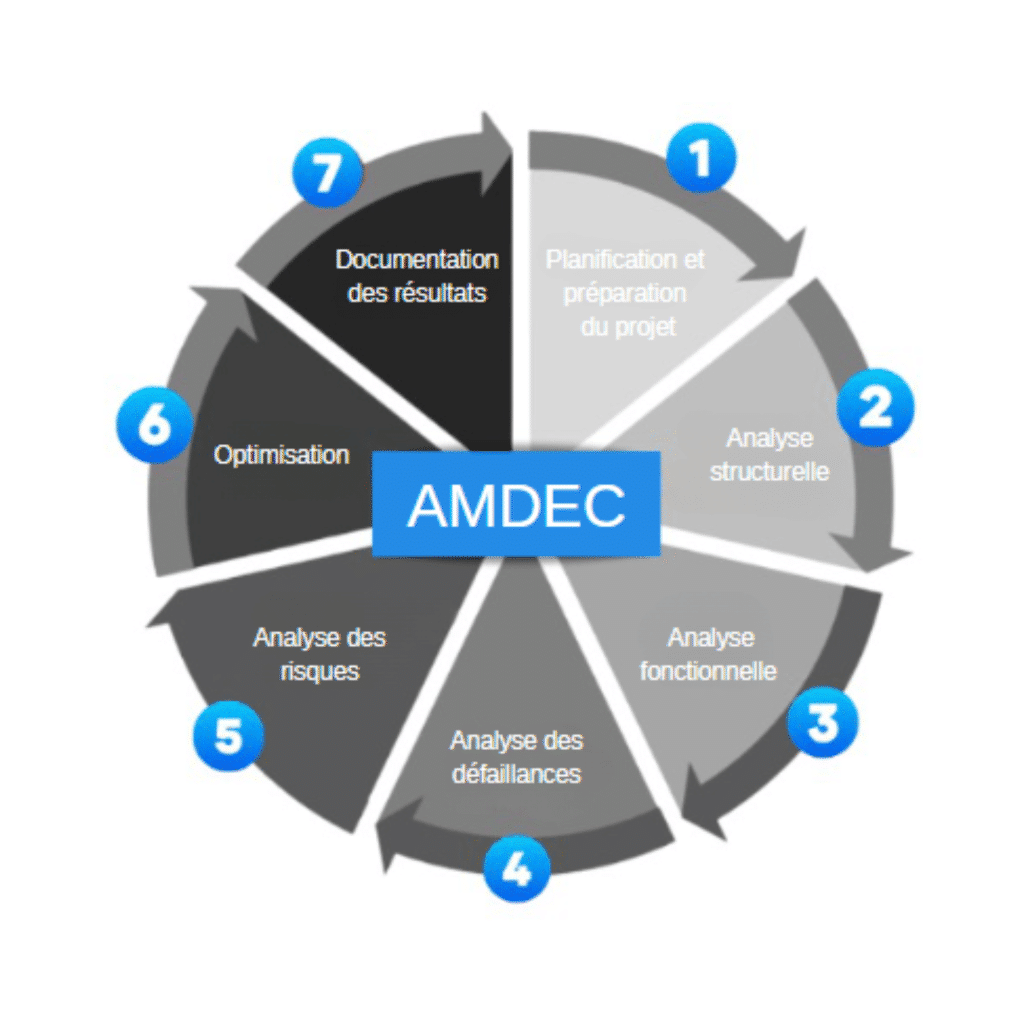

In addition to allowing suppliers to more easily meet their clients’ needs during the FMEA development process, the manual introduces major changes such as a new FMEA development process – the 7-step approach – and a new chapter on supplemental FMEA for system monitoring and response (FMEA-MSR). Other significant changes include the following:

▪️Fully revised severity, occurrence, and detection tables. ▪️The action priority (AP) methodology and tables replace the RPN. ▪️New spreadsheet forms (for spreadsheet users) and new software report views (for software users). ▪️The most significant change points from the AIAG FMEA 4th Edition Manual and the VDA FMEA Volume 4 Manual.

Emphasis on function-based FMEAs to the additional tools and guidance provided for supporting a more robust methodology, the new manual provides consistent direction and guidance to all automotive suppliers.

QUALIPRO has integrated all the AIAG VDA updates into its FMEA module.